Capacitors

There are so many things in life that I have overlooked, never understood, and am completely ignorant about. Capacitors are one of those topics.

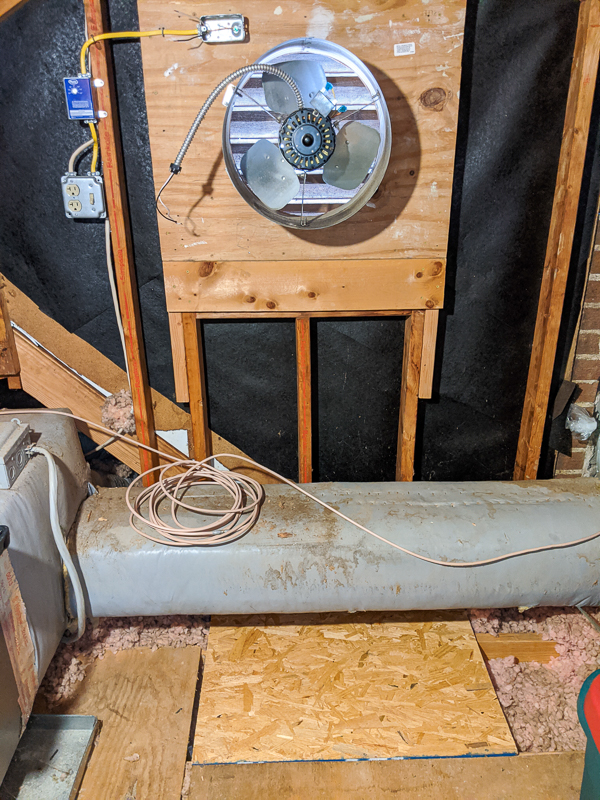

In the “It’s always something” theme, my son Morgan pointed out that, despite the 90+ temperatures, the attic exhaust fan was not turning on. He said loose plastic had gotten sucked into the fan, a casualty of a disorganized, cluttered attic.

Ok, stifle my “it’s broken and I don’t know how to fix it” canned life response and look at the problem—well, call Jeff for advice—then look at the problem. Not that many parts, how hard could it be!

Of course, the first issue was safety. After removing much debris and many boxes, I saw the floor immediately in front of the fan was unfinished. One wrong step would lead to a rafter wedgie and an embarrassing ER visit.

So off to the garage and found a suitable board lying around.

Was a breaker tripped?

I checked the breaker panel and all seemed fine. Of course, none of the breakers was marked for the attic. Ok, let’s figure out which breaker we need to turn off to safely work on the fan.

After several trips down to the breaker panel and up into the attic, I finally got smart and had Morgan help me. We communicated by cell phone. He would throw a breaker and I would see if the attic lights would go out. Nope, the entire upstairs breaker didn’t work, nor did the master bedroom, bathrooms, or GFCI breakers. We finally found that the one of the bedrooms was on the same circuit as the attic lights.

Great! Well not really.

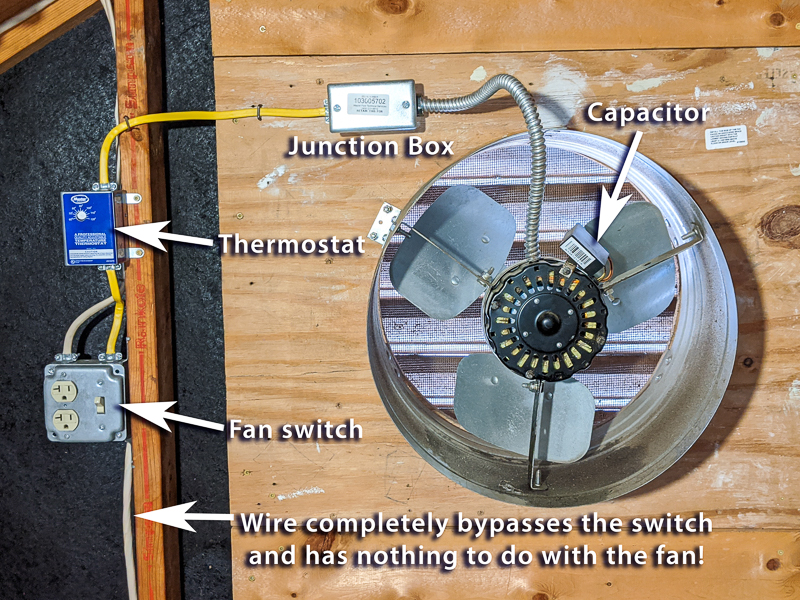

The attic fan was wired to a different breaker. It didn’t turn off when the lights turned off … AND … in the photo above you see a wire below the switch but IT DOESN”T POWER THE SWITCH! I was faked out as it stayed hot and the switch breaker was off. Criminy, but it makes sense, you don’t want to turn the fan off with the light switch.

More flipping of breakers and we found that the left front bedroom was on the circuit for the attic fan (opposite ends of the house). I immediately printed labels and stuck them on the breaker panel. Note: The wire below the attic fan switch remained hot all the time, it wasn’t on either the light or the fan circuit.

Is there power to the fan?

Was the wall switch controlling the fan broken? No, using a Klein voltage tester, I was able to check the wiring going into and out of the fan switch. The advantage of the Klein over a voltmeter is that it senses power through intact insulation for safe non-contact testing. I didn’t need to open the switch cover plate to apply electrodes.

Is the thermostat working?

I turned the thermostat down to 60 with the attic in the 90s but no start. I used the Klein tester on the wires into and out of the thermostat. No power out of the thermostat when set to 60 but immediately sent power when adjusted to 90.

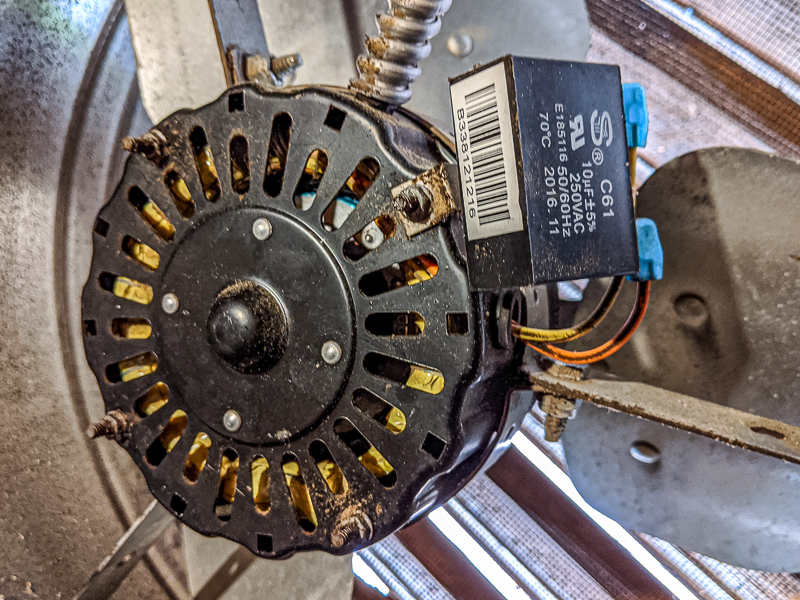

So the fan is receiving power but not starting. Maybe the fan motor is bad and what is this dodaddy thing on the side of the fan?

A capacitor

Turns out capacitors are everywhere but I fail to notice them. They are analogous to the starter in your car and the ballast in fluorescent lamps. Unlike batteries that store electricity chemically and release it slowly, capacitors rapidly store up a charge electrostatically (think getting shocked in winter when touching something metal) and release it rapidly to kick start electric motors in your HVAC system, fans, refrigerators, washers, dishwashers, and dryers. If you have an old shop tool like a sander that used to work but won’t start now, it is likely that the capacitor failed.

Ok, how do you check whether the capacitor or the motor is bad? Worth asking the question since the former costs less than $10 and the latter close to $100.

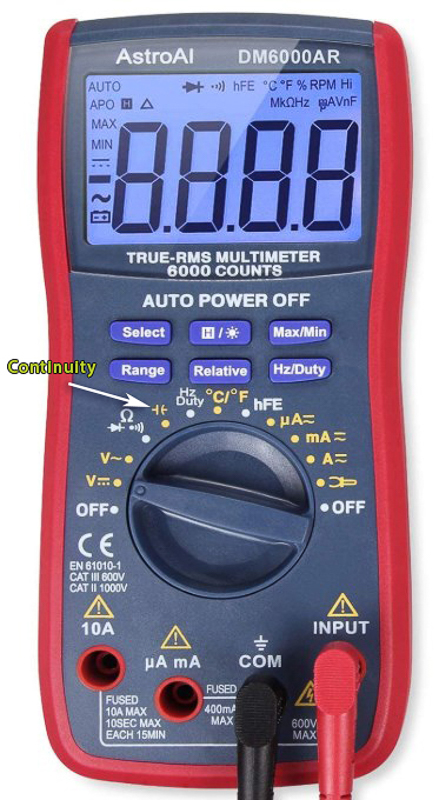

You use a multimeter. Of course, I have three but none of them has a capacitance mode. Didn’t know there was such a thing—or how to use it.

Ok, so I ordered an AstroAi TRMS 6000 Digital Multimeter from Amazon with one-day delivery.

In the meanwhile, I went to Home Depot for an unrelated item and while there wandered into the attic fan section and found my current fan, a Master Flow EVG5—but made a rookie mistake. I knew I was making the mistake but made it anyway. There were only two fans left, one in a badly ripped box (never a good choice) and the other in my hands. I thought, “the multimeter will be at the house later today, so I’ll test the capacitor first, and maybe save money”.

Bad thinking. Low on stock, middle of a July heatwave, other people will need one too.

Always buy the item and return it unopened if necessary. I went home, unpacked the multimeter, watched some YouTube videos on measuring resistance and capacitance, and went into the attic.

The resistance of the two motor wires should have been low but showed no connection, that is, the wiring in the motor was non-conductive. Bad sign, indicating a failed rotor.

The capacitance was spot on at 9.99 for the capacitor rated at 10 microfarads +- 5% (per the label on the capacitor).

With this knowledge, I drove back up to Home Depot—just a few hours later—and the fan was sold. The only one left was the one with rip.

So what had I learned to this point?

- Think through the problem

Know what can fail, in this case, the switch, the thermostat, the motor windings, or the capacitor. The history of plastic getting sucked into the fan pointed to the motor. Jeff told me it was the motor. I knew it was probably the motor. I wanted it to be the capacitor. The problem didn’t care would I wanted it to be. - Know how to test

- The switch by testing pre and post switch current.

- The thermostat by testing pre and post thermostat current while making temperature setting adjustments.

- Motor windings by testing continuity of the wires into and out of the motor. If there is no continuity then a wire is broken.

- The capacitor by measuring capacitance and comparing it to the rating.

- Own good tools

In this case, a very good multimeter. - Know how to use your tools

In this case, using resistance to measure continuity and the capacitance setting. - Work safely

Repeatedly test the wires before you touch electricity. Clean up your work environment—remove boxes, debris, and fix the floor. - Don’t lock onto your first thought

With no evidence, I was really convinced it was a bad capacitor because they were new to me. This tendency to hold onto the first idea shaded my judgment. Yeah, if you have a new hammer everything looks like a nail. - Buy the item when you see it

Buy the item and return it later if necessary. Don’t think about saving money, you aren’t. You are wasting time. Home Depot has a great return policy. This is a good example of knowing my personality yet not overcoming it. I really dislike returning items to a store so the combination of “let me check the capacitor first” and “I can always go back and buy the item” won out even though I knew the right thing to do and the item was in my hand. - Ask the store clerks

I have another personality trait related to my shyness and introversion, I don’t like to ask strangers for anything in person or on the phone. I have to fight it all the time, yet when I do ask it always turns out fine.

Though I had the Home Depot app open on my phone to find the Aisle and Bin location, I was frustrated and left the store without seeing that the app listed nine in inventory, the ripped box and eight others. Sure, the app may have been wrong but AT LEAST ASK!

Another of my personality faults, male blindness. All the women reading these are nodding their heads.

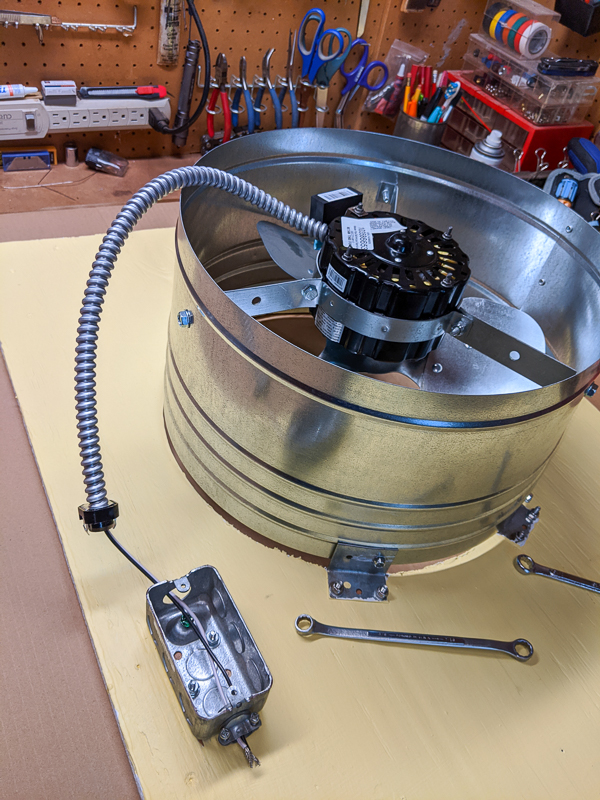

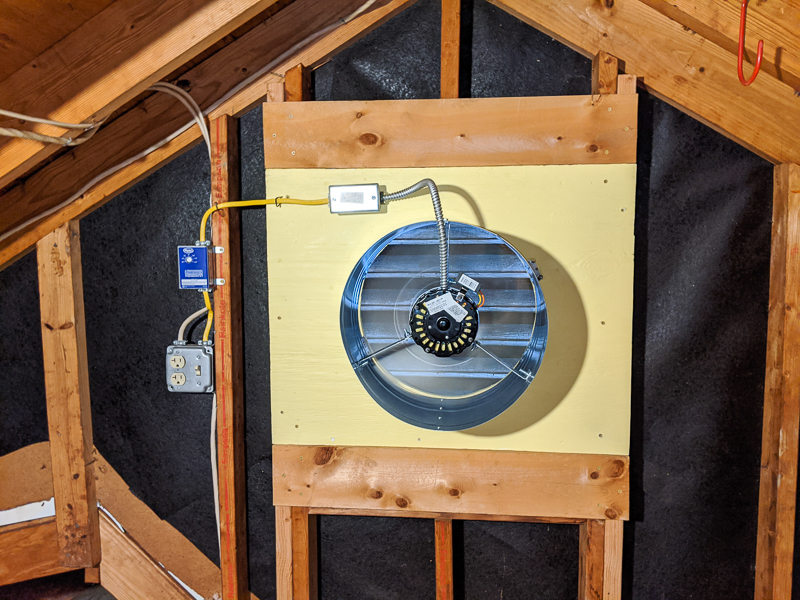

So, I bought the fan and, as with all home improvements, I underestimated a repair time of an hour to remove eight nuts, take the old fan off, put the new fan on, tighten the eight nuts and reconnect two electrical wires with wire nuts.

Simple! Well no

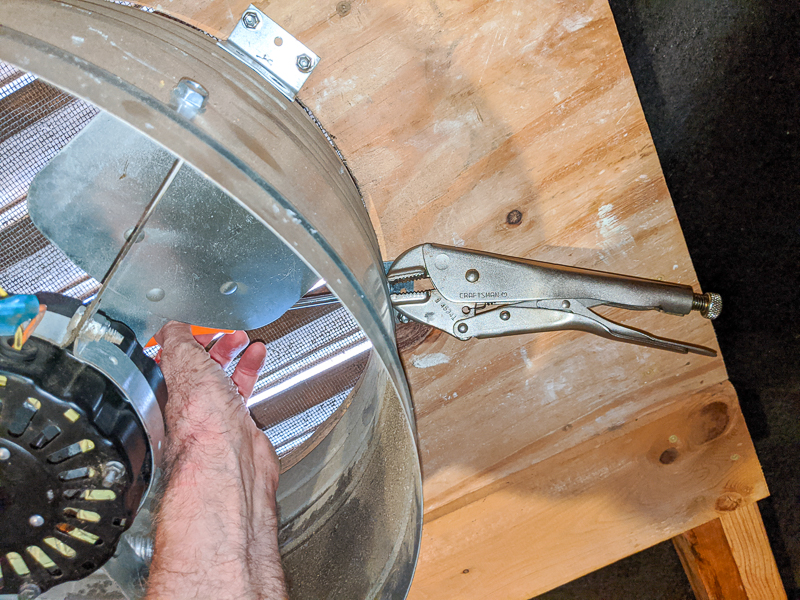

Four of the eight nyloc nuts (plastic centers to prevent slipping from all the vibration) would turn but not unscrew. They just rotated and would not come off.

So, I removed the mounting board and took the whole thing out to the garage. It was over 100 degrees in the attic so I should have thought of this sooner. Yes, Jeff told me at the start to take it out of the attic because of the heat but I didn’t see the need. This was a quick replacement. Right? He was right.

Got the nuts off and put the new fan on but the wire conduit wouldn’t reach the junction box. Ok, this one was easy, just loosen the motor mounting nuts, rotate counter-clockwise and retighten.

So I don’t think my lifelong difficulty with handiness is due to a lack of intelligence but is far more influenced by my reluctance to ask for help (sales clerks), jumping to the first solution (the capacitor), not seeing what is directly in front of me (male blindness), and cutting corners to finish faster (not taking the time to remove the fan from the attic).

I hope that by knowing my faults, I can work around them. One positive, I was perseverant and keep plugging ahead.

In the end the fan was fixed properly.